Quick And Dirty Thermal? | ||||

|

Before reading this section, we recommend that you look through Sauna Overview. Some people think that thermal simulation starts with a completed board layout. It doesn't. Before PCB layout, some basic decisions need to be made. Will an external heat sink be required? Is a fan necessary? How should components be positioned? Will a metal core board be needed? Some of these are go/no-go decisions. After all, there's no point in doing a full PCB layout if the project is unfeasible. Companies need a thermal tool for quick analysis. Sauna is the thermal simulation package which provides for both "quick and dirty" analysis and detailed models. Quick and dirty components

Sauna provides two different ways to model heat generating components:

basic heat sources and enhanced heat sources. Both heat source types

allow for heat flow through the bottom of the component. However, only

enhanced sources allow for lead connections. For quick and dirty modeling,

you would use either basic sources or an enhanced source with simplified

pads.

In addition to individual heat sources, you can also apply distributed wattage to plate and board assemblies. You can apply the wattage to the entire assembly or you can assign wattage to a specific zone. Quick and dirty heat sinks

Heat sinks are rather easy to model with Sauna. So to some extent, all heat sink modeling is "quick and dirty". Actually, it's more like "quick and clean", because the accuracy is excellent. As described in Sauna Overview, heat sink modeling is a simple process. After creating the baseplate, you can add fins to one or both sides with a single command. Complex shapes are created by combining plates in different planes. For heat sinks you can use basic sources and obtain accurate results. Several options are available for forced air cooling. You can specify a linear flow rate (m/sec of ft/min), a volume flow (m3/hor or CFM) or you can define a fan. Heat sink modeling is fast and accurate with Sauna. Quick and dirty boardsFor quick and dirty board applications, there are two different approaches. First, the simplest method, is to use a "planar" board assembly. For planar boards, you do not define individual traces and pads. Instead, you adjust the copper coverage (sometimes know as "copper density"). The planar board is a great tool for obtaining quick results, particularly for components with heat slugs.

The second quick and dirty approach is to create a layer by layer stackup, but with simplifed enhanced sources and fewer traces. While the examples in Sauna Overview show individual traces for each lead, you would use "lumped leads" for a simplified model. With lumped leads, a large pad of reduced copper coverage is created to combine traces. Also, in a simplified model, most components will not be connected to other components. In fact, for heat slug components which are connected to an internal plane, you could skip traces entirely. All of the components in Sauna's library include typical data for Rjunction-to-case and Rcase-to-sink. So you can get an idea of thermal performance without using a datasheet, which is quite useful for initial analysis. Quick and dirty boxes

In Sauna, a box is created with a single command. It's very easy to add fins to any of the outer surfaces. To add a circuit board, Sauna provides the "board in box" command. For internal convection and radiation, Sauna has specialized commands for defining internal networks with either natural or forced air cooling. So you can create a model of a box with one or more boards in just minutes. As you have seen, Sauna is a great "quick and dirty" tool for everything from heat sinks to boxes with boards. Another approach: Sauna's ToolboxWith all of the techniques described above, you will create a Sauna model. But it's also possible to obtain thermal results without a model. Sauna's Toolbox gives you access to a variety of thermal calculations. For example, if you want to calculate the wattage dissipated by a 100 mm x 100 mm plate with a temperature rise of 35°C at an altitude of 4,000 meters, you can use the Toolbox to get an answer. The Toolbox gives access to a variety of convection and radiation equations, including radiation view factors. You can also calculate the thermal resistance of a variety of shapes (bars, wires, tubes, etc) and there are electronics-oriented resistances as well (thermal via resistance, end-to-end trace resistance and more). Although people don't buy Sauna for the Toolbox, most users use it frequently. Interacting with FEM and CFDYour company may already own an FEM (finite element method) or CFD (computational fluid dynamics) software package. And, in fact, you may be the user of one of these packages. So does it still make sense to purchase Sauna? The answer is "yes". Users with access to multiple packages simply choose the best package for a particular need. Sauna is well suited for many thermal problems but there are times that CFD is useful for a complicated air flow pattern. And FEM packages can predict mechanical stress, which Sauna can't do. Actually, Sauna can be used to complement a CFD or FEM analysis. A quick Sauna model is very useful as a check on the CFD or FEM results. Also, FEM packages only have limited ability to calculate convection and radiation boundary conditions. So you can use Sauna's Toolbox to calculate the necessary boundary heat transfer coefficients. This is another common use of Sauna. Sauna is an excellent thermal package for a wide variety of uses. |

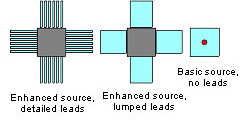

Detailed and simplified heat sources

Detailed and simplified heat sources

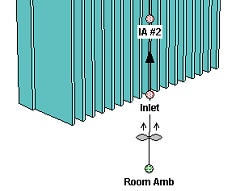

Fan applied to heat sink flow network

Fan applied to heat sink flow network

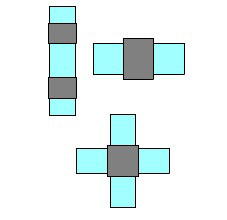

Dual and quad components with lumped leads

Dual and quad components with lumped leads

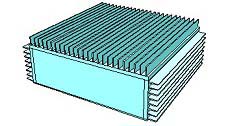

Finned box, easy to model

Finned box, easy to model